Ginning: Cotton Ginning, Process, Types, and Objectives

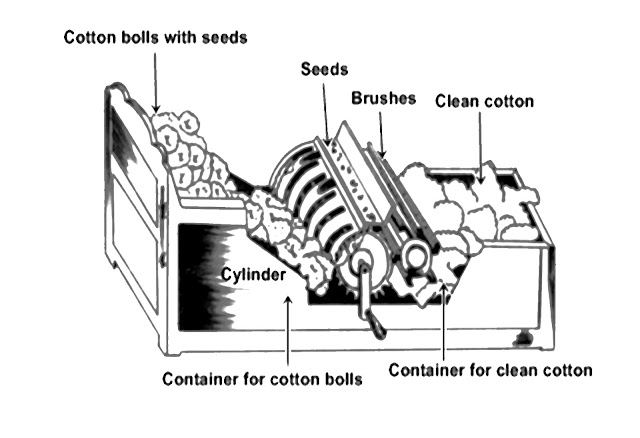

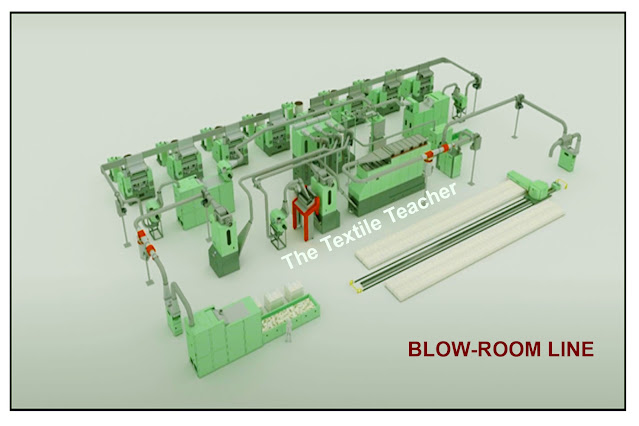

Ginning is one of the most important step of spinning process. After collecting seed cotton from the farm or field, cotton moves to nearby Gins for separation of seed, lint and any other foreign particles.

Simply to define ginning we can say the process is used to get the cleaned cotton by separating or removing the seeds, dust or any other foreign particles, so that better cotton can be offer for the cotton spinning mills.

Objects of Ginning:

∎ To make the fibre-free from seeds.

∎ To produce good quality of cotton fibre.

∎ To collect the fibres and seed separately.

∎ To make the spinning process easier and effective.

Lints: Lints are the long cotton fibers that are recovered from seed during ginning.

Linters : Linters are the thinner cotton fibers that stick to the cotton seeds after a cotton gin separates the seeds from the thicker cotton fibers–the cotton lint.

Main Factors

- Length

- Fineness

- Maturity

- Uniformity

- Trash Content

- Cohesiveness

- Strength

TYPES OF GINNING

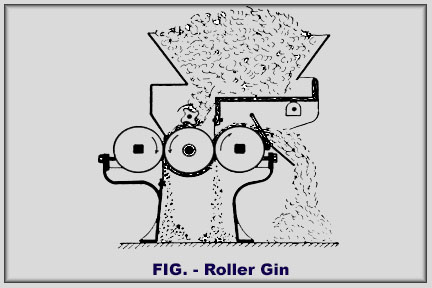

1. Roller Gin

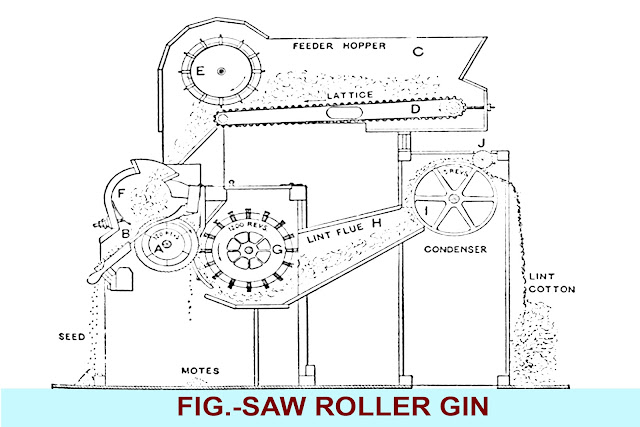

2.Saw Gin

2.Saw Gin

thc drink mix online for instant infused beverages

Been messing around on 52bet1 for a bit. Seems like a reliable spot with some good odds. Might be my new go-to. You can try it out here: 52bet1.

J9bet – Has anyone had a positive experience cashing out? I’ve read a few conflicting reports. I’d love to try it, but super nervous about slow withdrawals. j9bet

Just discovered betrupeesgame and I’m hooked! The games are actually pretty fun, and the payouts are decent too. Good way to kill some time and maybe win some money doing it!

Just wanted to give a shoutout to vf555casino. Been having some fun here, especially on the live dealer games. Good variety and decent odds. Take a look, maybe you’ll find something you like: vf555casino

Alright, 789win77. Hmm, it’s got potential. Maybe could use a little tweaking, but overall, not a bad experience. Worth checking out, just sayin’. Find it here: 789win77

G88club, alright! This one’s got a good vibe going on. Feels like everyone’s just hanging out and having a good time. Join the club! Find it here: g88club

B88 club… it’s got a good vibe. Feels like a classic online casino, you know? Good selection of games, too. b88 club

Alright, for all my football fanatics, bongda789p got you covered. All the matches you could want. Get in on it! bongda789p

Looking to download Selcuksports? Heard it’s the way to go for streaming. Get that ‘selçuksports indir’ sorted and enjoy the game! selçuksports indir

PHGreatCasino, tried it out. Nothing mind-blowing, but not bad either! You may find your next favourite game there. Try it here if you like, mate: phgreatcasino

Right then, 89kbetvn. Decent site for a punt. Nothing overly spectacular, but it does the job. If you fancy a quick flutter, why not? Check it out: 89kbetvn

Alright, guys, checking out vin777com! Heard they’ve got some sweet slots. Fingers crossed for some big wins! Definitely gonna give vin777com a shot and see what’s up.

Wi55vip is where it’s at for some chill casino action. The bonuses ain’t too shabby and the game selection is pretty good. Haven’t tried their VIP program yet, but planning to soon! wi55vip.

Okebet4login is pretty straightforward for getting back into your account. No crazy hoops to jump through. Simple and effective login process, which I appreciate okebet4login.

Stake777 is all about high stakes, and I’m here for it! Decent platform, responsive, and seems trustworthy enough. Remember to gamble responsibly, peeps! stake777.