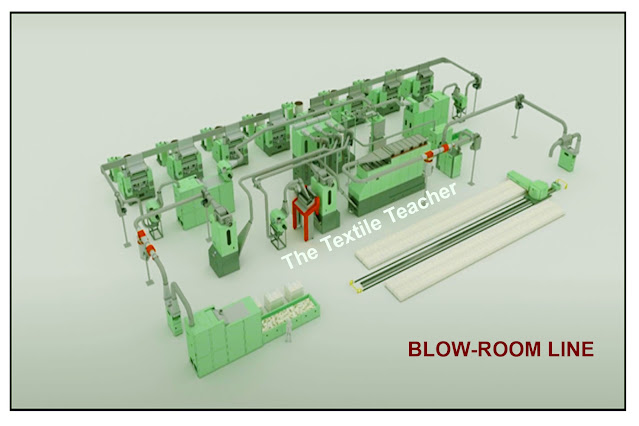

Blowroom:

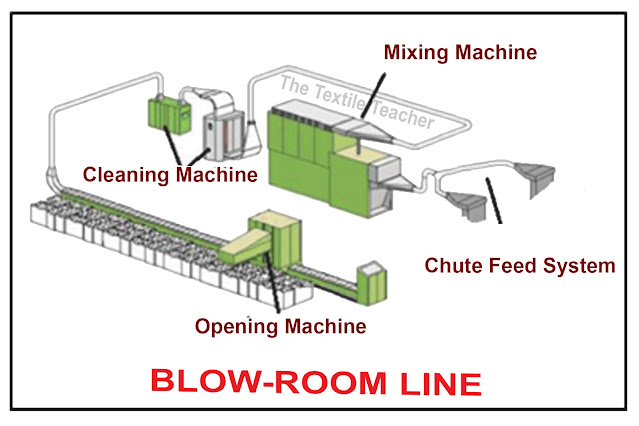

The section where the supplied compressed cotton bale turn into a uniform lap of particular length by Opening, Cleaning and Mixing or Blending is called as Blowroom Section. The Blowroom section is the starting department of spinning mill/unit.

Object of Blowroom:

Opening:

Opening:

1) Opening of compressed cotton bales and are made into small tufts. This is the first operation is required in the blowroom line is OPENING. Bale opening consist of opening the fie bales and converting them into small fibre flocks.

2) The Fibre flocks are removed mechanically with the help of beaters. And the fibre flocks are transported by air through pipeline to next process.

Cleaning:

Cleaning:

1) Separation of Fibre flocks and removal of contamination particles and dust from the cotton.

2) To eliminate dust, dirt, broken leaf, seed particles, grass and other foreign impurities from the cotton fibres/flocks.

Mixing/Blending:

Mixing/Blending:

1) To produce a comparatively good quality of cotton fibres by mixing diffrent types of fibres like Cotton-Viscose, Cotton-Polyester.

2) The Blending of fibre material is essential preliminary in the production of yarn. The fibres can be blended at various stages in the spinning process.

Lap Forming:

Lap Forming:

To convert the opened and cleaned fibers into a sheet of particular width with uniform mass per unit length is called LAP. The Lap is wound on the spindle to make it suitable lap for the next process of carding.

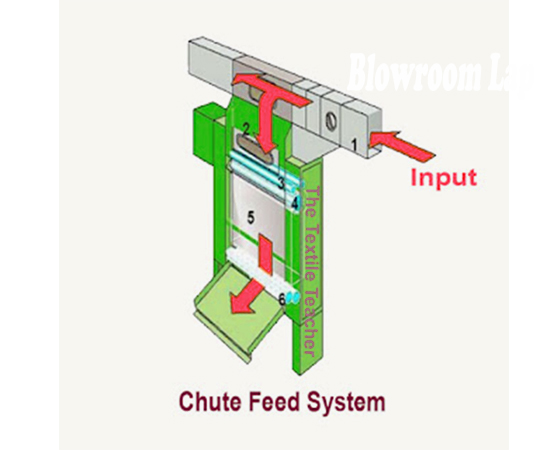

Chute Feed System:

Chute Feed System:

The Chute Feed System is a automatic process of LAP formation, The Blow-room Lap is fed to the Carding, instead of forming blow room lap, the opened, cleaned, mixed/blended material is fed to the Carding Machine through pipeline in small tufts by air. The Uniformed sheet like Lap of particular width and mass per unit length is called Chute Feed System.