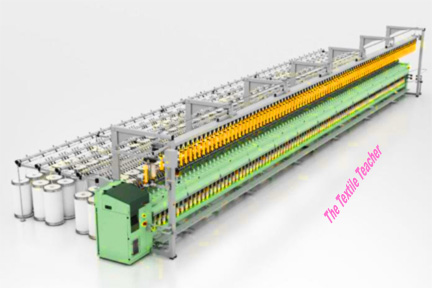

Speed Frame Machine

The speed frame is an intermediate machine between draw frame and ring frame in which fibers are converted into low twisted strand called Roving. Input of speed frame is sliver and its output called roving. The speed frame is called by various names in industry as Simplex, Roving frame, Fly frame.

OBJECTIVES OF SPEED FRAME MACHINE

- To reduce weight or mass per unit length by drafting the sliver.

- Conversion of sliver into roving.

- To insert small amount of twist.

- To wound twisted strand on the bobbin.

- To make tapper or conical shape of the bobbin.

PARTS OF ROVING FRAME & ITS FUNCTION

-

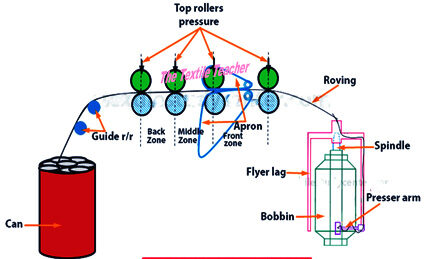

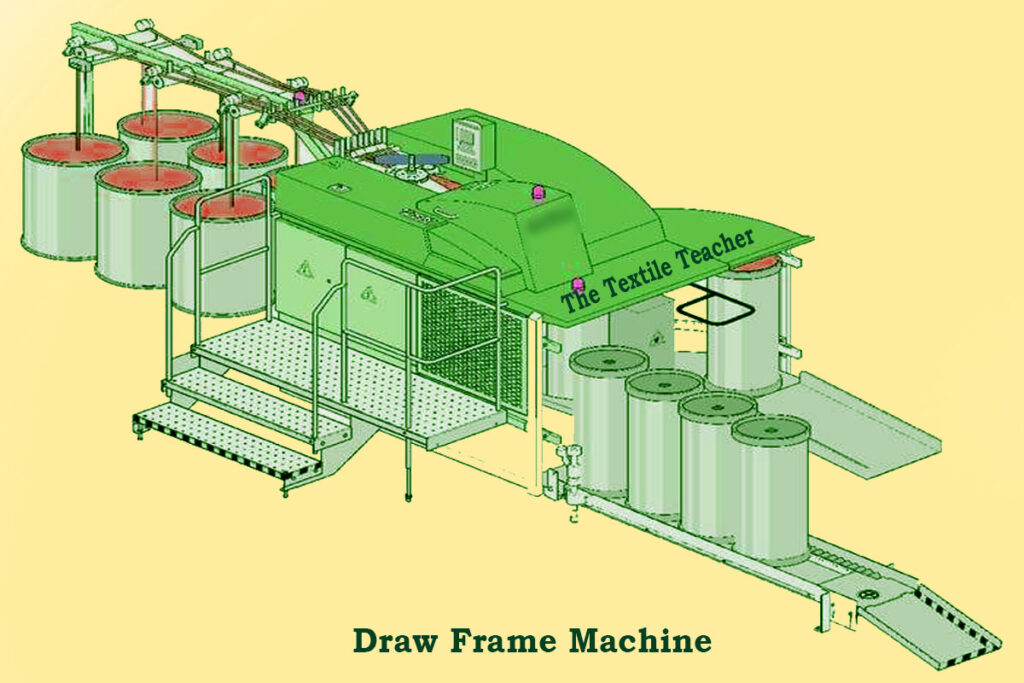

Creel:

Creel is used to guide the sliver. Creel portion is present above the can. Creel helps Sliver along the way to arrange a draft without any mess.

-

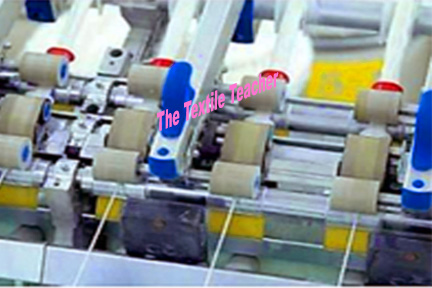

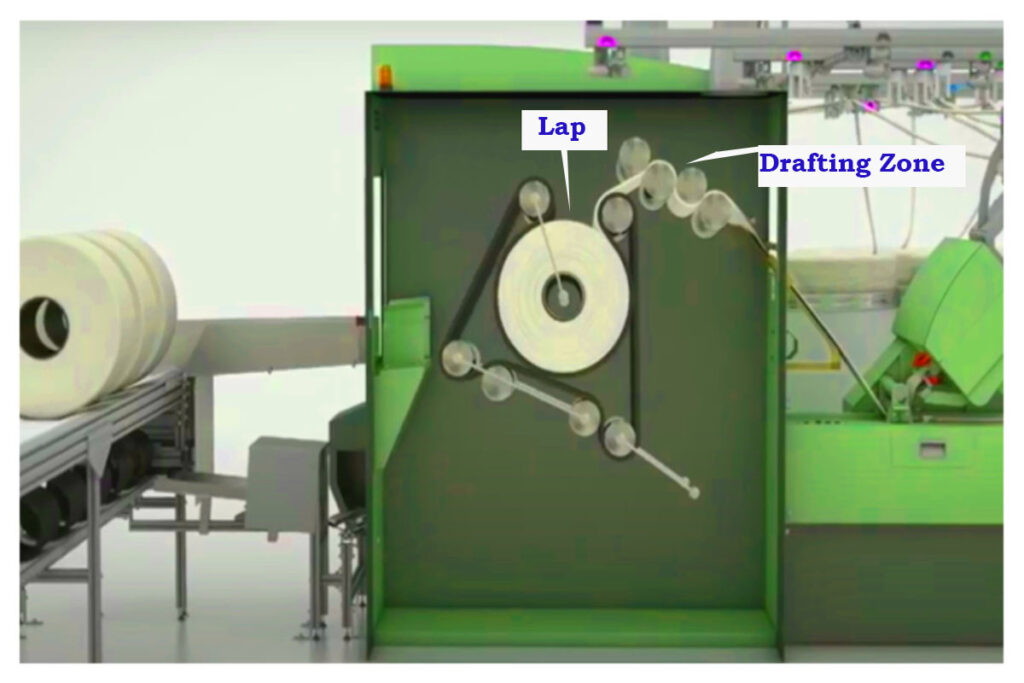

Drafting:

To reduce weight or mass per unit length by drafting the sliver. In the drafting zone pneumatic pressure is applied over the drafting rollers and the speed difference between the drafting rollers, drafts the sliver to desired hank.

-

Twisting:

The drafted slivers delivered are too thin to hold themselves together and slight twist is needed to strengthen the roving to prevent breakage during next processing. The drafted strands of fibres are passed from drafting zone to flyers for twisting.

-

Winding:

The flyers provide twist to the fiber strands and make the roving strong enough to be wound onto bobbins and processed in a ring frame.

-

Building:

The up and down traversing of the bobbin rail makes the bobbin to be conical or tapper shaped.

-

Doffing:

When the roving bobbins become full the machine is stopped and doffing takes place to remove full bobbins and to fix empty bobbins with required length of roving manually wound on the empty bobbins through Flyers for continues working.

-

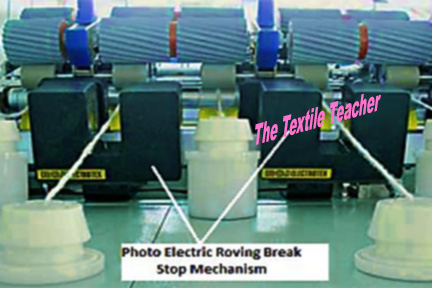

Roving & Sliver Breakages Stop mechanism:

Photo electrical sliver and roving break stop mechanism. When-ever sliver or roving breaks due to any reason machine stops.

Just gave hackerslotpg a whirl! Not bad, decent graphics and a few lucky spins. Gonna check it out again later I think. hackerslotpg

Gave shbet800com a whirl and it’s…okay. The interface is a bit clunky, but the games are fun enough. They could definitely work on the user experience, but it’s passable. See for yourself: shbet800com

Looking for some good affiliate programs, and dafabetaffiliates.net seems legit. Checking out what they’ve got to offer. Fingers crossed for a good partnership! Check them out here: dafabetaffiliates

Hoywingame is my current jam. It’s one of those games you can’t put down. Seriously, I started playing like a week ago and my social life is gone. Play if you dare: hoywingame

So, if you’re already in with Fundalor, Fundalorlogin is where you probably wanna be. Get in there and win big, dude. Here’s the entry point:fundalorlogin

Alright, coderemexico, let’s see what you’ve got. New to the scene? Always looking for something fresh. Check them out: coderemexico

Looking for some mobile gaming action? 1JJGameDownload might have what you need. I might just see if they have a new version of Call of Duty. See what they got at 1jjgamedownload.

Bet83, eh? Never heard of them, but willing to give anyone a fair shot. Might check out their odds on the races this weekend. Investigate for yourself, bet83

Trying to get back in? Best bet is to try and log into lucky888login. Hopefully ya remember yer password. For lucky888 login.

Alright, so I gave lucky777lucky100lucky a shot, and I gotta say, it delivered. Very easy to use, and works for what I needed. You should totally check them out, link below. Access it here: lucky777lucky100lucky

555phslot! A friend told me about this one. Gave it a try and actually won a little something! Easy to navigate and good selection. My experience was positive. Check it out here 555phslot

7wgcasinologin – Heard good things about this. The login process seems straightforward and secure. That is a big plus in my book. Give it a go, here 7wgcasinologin