Ring Frame

A ring frame machine is a key piece of equipment in the textile industry, primarily used for spinning yarn. The main function of the ring frame is to attenuate and twist the fibers into a continuous yarn. This machine is used for to spin the Polyester, Viscose, Cotton, Wool, and their blends. In this process the roving are drafted, twisted & finally we get yarn.

Objectives Of Ring Frame Machine

- To manufactured particular count of yarn from the speed frame roving by drafting.

- To spun the fibers stand and convert it into continuous yarn by drawing and twisting them.

- To manufactured yarn with uniform thickness /evenness, strength, and smoothness.

- To create yarn of varying thickness (fine to coarse) according to fabric requirements.

- To produce yarn with minimal defects like slubs, lumps, or uneven texture.

- To wind the yarn onto the bobbin.

- To build the yarn package properly.

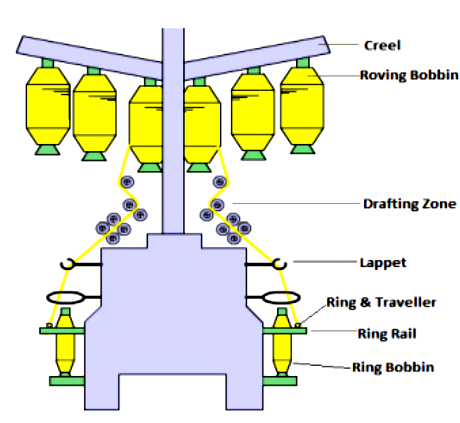

Parts Of Ring Frame & Its Function

Creel:

In a ring frame machine, the creel is considered to be one of the most fundamental stages that prepares and feeds roving to the spinning process. The creel is that part of the ring frame machine which holds up and supports the roving bobbins and provides for a smooth and uninterrupted supply of roving to the drafting system of the ring frame.

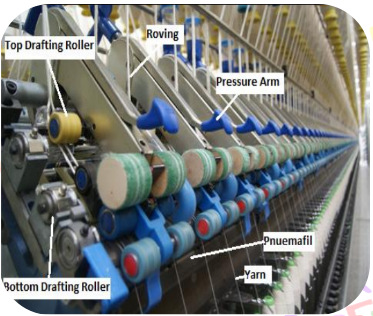

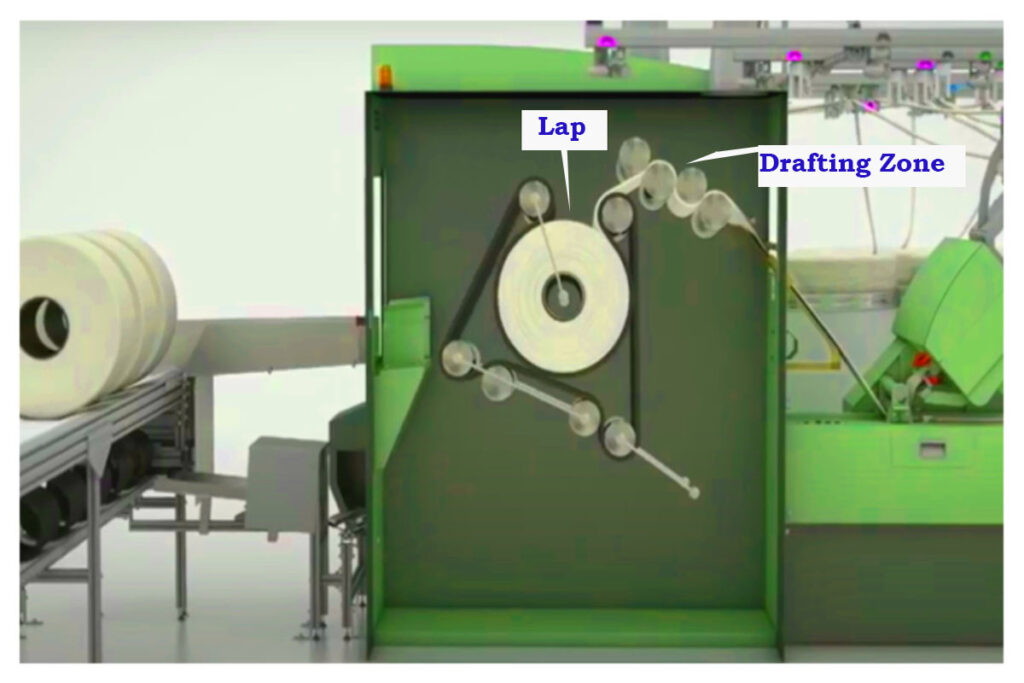

Drafting:

In drafting system reduction in mass or weight per unit length. In drafting roving attenuates to the desired fineness by applying the required draft to the roving by the top arm pressure and variations in a speed of series of drafting rollers.

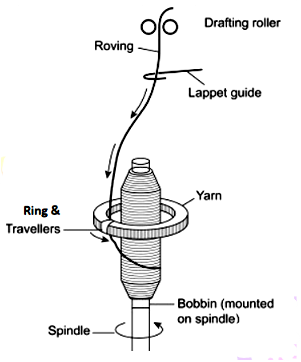

Twisting:

A certain amount of twist is inserted into the fibres strand. This twist helps to hold the fibres together in the yarn. The spindle rotation at very high speed and twist is inserted to the yarn. The traveler rotating on the spinning ring inserts one turn into the yarn after the completion of each revolution.

Ring & Traveler:

The ring enables the insertion of twist into the fiber strand by allowing the traveler to rotate around it. The number of twists per inch (TPI) inserted into the yarn depends on the rotation speed of the spindle and the movement of the traveler around the ring. The circular ring guides to the traveler. The delivered drafted fibre strand by the front rollers. The travelers and ring enable to wound the yarn onto the bobbin & maintain uniform winding tension of the yarn.

Pneumafil :

The function of pneumafil is when end breaks occur from front roller it collect by the pneumafil suction system mounted at below front roller.

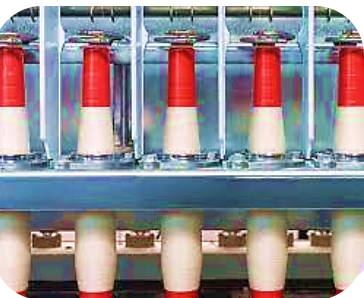

Winding:

In a ring frame machine, the process of winding yarn onto a bobbin is an integral part of the spinning operation. The winding mechanism in a ring frame is crucial for producing a uniform and consistent yarn package, which plays a significant role in the efficiency of subsequent textile operations. This component helps guide the bobbin during the winding process and controls the tension and winding pattern.

Building:

To produce conical or tapper shape of the ring cops.

Doffing:

To replace the full length ring cops with empty ring cops. (Automatic or Manual)

Bong365bong88 is the place to be for serious sports betting. They’ve got all the markets you could ask for, and their live betting platform is top-notch. If you know your sports, you can definitely make some money here. Check it out: bong365bong88

F9games, huh? New platform? What kind of games are we talking about here? Any hidden gems? Let me know if you’ve played and enjoyed! More info: f9games

Hmm….taiHM88. Not the flashiest site, but it gets the job done. Payouts were reasonable and the selection of games is growing. I reckon it is worth giving a whirl!!! taihm88

70bet12, huh? Heard murmurs about this site. Gonna peek in and see what’s up. Might be my next go-to place for some fun!. Give it a shot 70bet12

9dbetbr is new to me, bro. The graphics look sharp! Checking it out now and will let you know how it is. Check them out 9dbetbr

Yo fam, b2xbetlogin! Heard it’s easy to set up an account. I will check it out later!. Take a peek for yourself b2xbetlogin

X89login made my life easier! The login process is super quick. If you’re looking for something simple and efficient, this is it! Totally recommend. x89login

Gave wi5599k a shot, and I was pleasantly surprised. The interface is clean, and the bonuses are pretty generous. Worth checking out. Check it out here: wi5599k

Vin55’s got a decent selection of games, and the platform is smooth. I wouldn’t call it life changing, but definitely worth a look if you’re browsing. Check it out: vin55