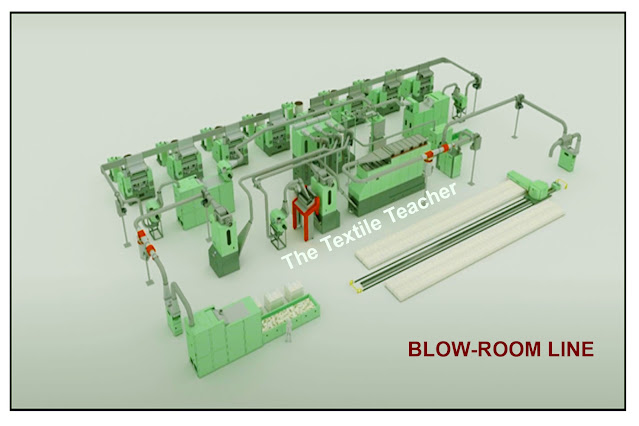

Lap Former Machine:

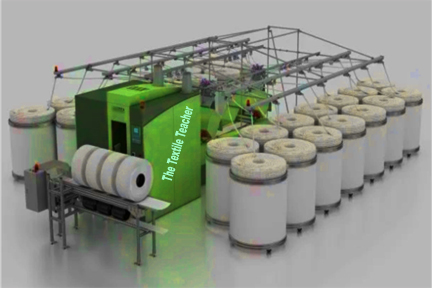

To produce better quality of cotton yarn means combed yarn, we required two more extra machines in our spinning section comparing to conventional carded yarn production process. Lap former are to produce regular laps, after that comber machine to transfer those laps into uniform slivers.

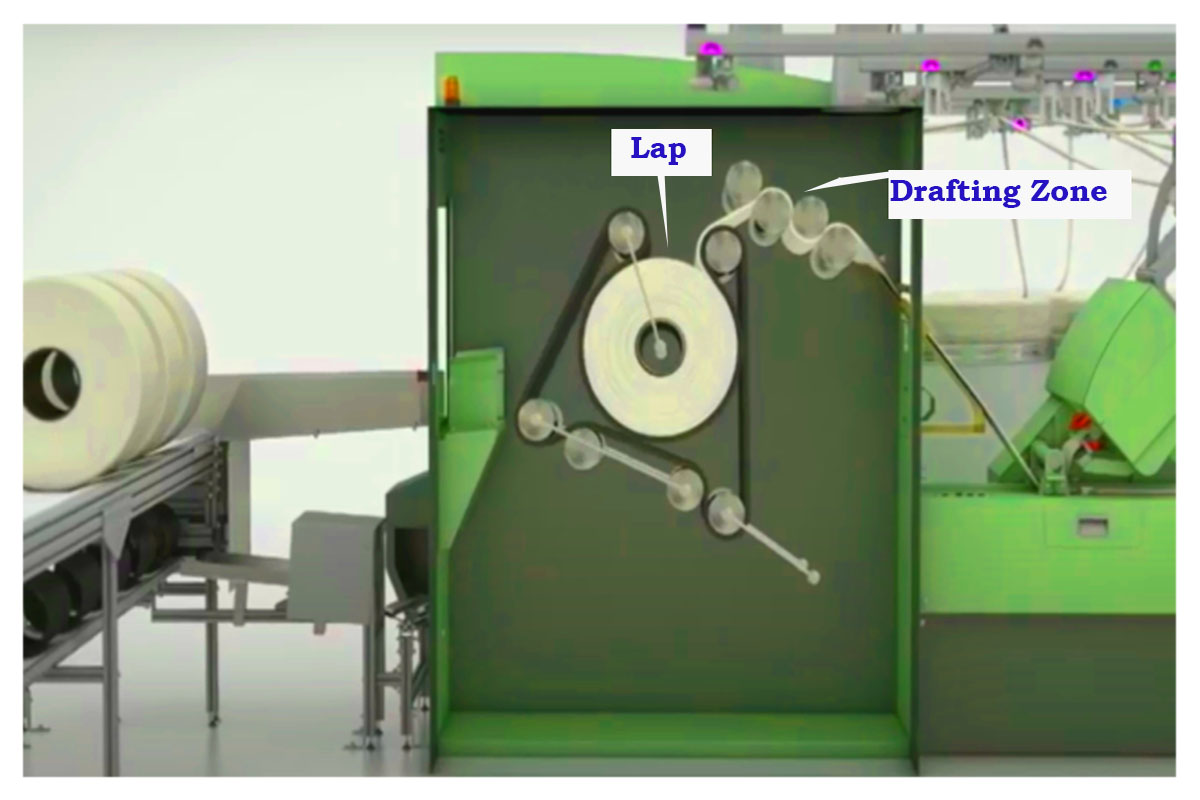

The Lap former machine forms the lap by sliver doubling (16 to 32 slivers) The slivers are fed to the lap former machine in side by side passing through the guide rollers and stop motion. To produce a compact lap enters the drafting zone and then calendaring zone. Then lap is wound on to the bobbin.

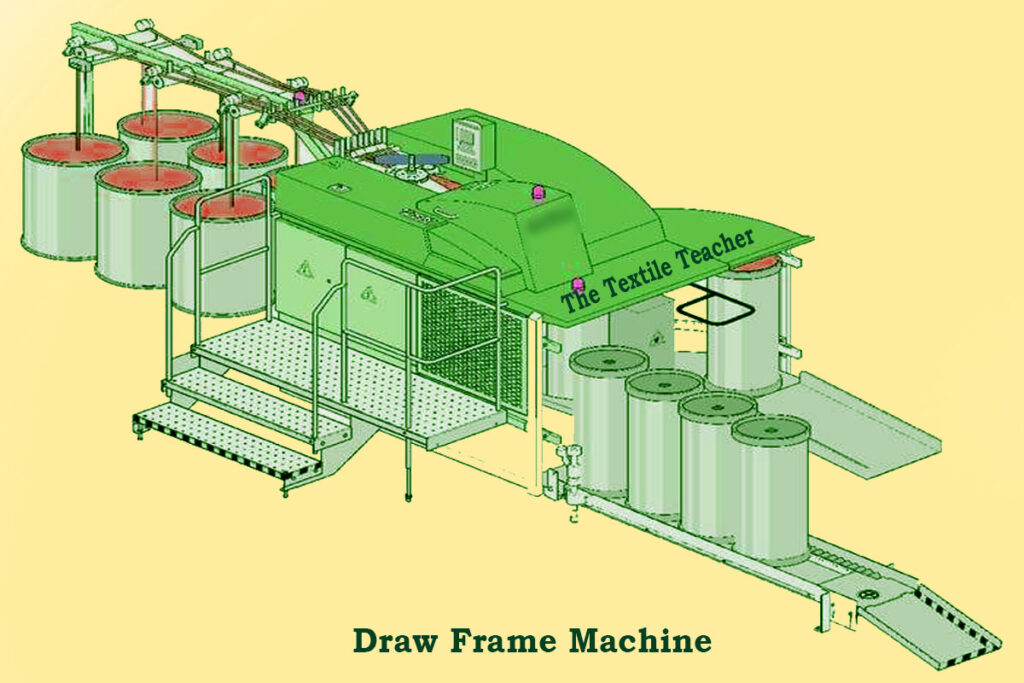

Lap former machine is a important machine for produce lap in spinning line. The Lap former machine is used for the production of lap. It is used after completing the process of blow room, carding or draw frame.

Types of Lap Former Machine:

A. Sliver Lap Former

B. Ribbon Lap Former

A. Sliver Lap Former:

The sliver lap machine is to produce a lap from several carded slivers. The use 18 to 24 slivers depends on the width and mass per unit length of the lap are required. The sliver lap sheet runs through the two pairs of calendar roller which helps to compact it into a sheet.

B. Ribbon Lap Machine:

The ribbon lap machine is used for doubling of lap which is produce in sliver lap machine. The machine is made lap from 6 to 8 sliver lap depends on the width and mass per unit length of the lap are required.

Objectives of Lap Forming Machine:

I) To doubling of Draw frame or card slivers.

II) To impart optimum draft to the feed material.

III) To calendaring of the material to form lap.

IV) To winding of the lap on Spools.

V) To doffed the fully wound Lap.

Features of Automatic Lap Former Machine:

1. Automatic doffing of fully wound laps.

2. Automatic stop motion works at sliver breakage and at the time doffing.

3. Auto grain adjuster.

4. Automatic leveling.

5. Automatic lap carry device.

6. Indications of lights for faults may occur in machine.

7. Automatic Lap length measuring device.

The Lap forming is the important process before combing operation, which affects the quality of the comber sliver. The needs of the lap for the better performance of combing are great fiber orientation, and uniform thickness. The comber machines are fed with lap manufactured by doubling of slivers and webs.

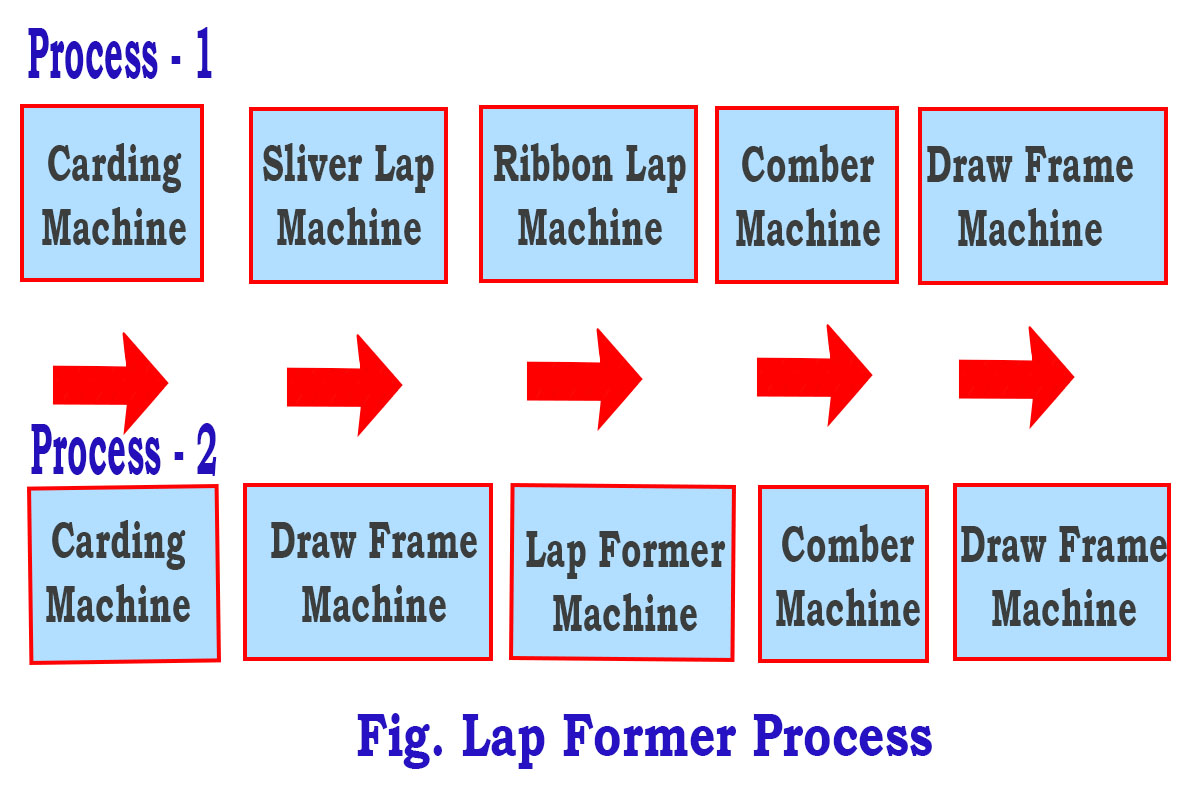

The laps are prepared with proper doubling and draft may enhance the uniformity of the output sliver. The lap sheet produces a highly uniform combed sliver with a high degree of evenness. Great fiber orientation is a prerequisite in the feed lap along the length of the feed lap to achieve better sliver quality. Lap can be produced by different process as shows in Fig.

The Sliver lap former and ribbon lap former is used to produce the lap by doubling certain no. of slivers and webs, respectively. The other process has sliver doubling machine is called super lap former M/C, used for lap preparation. Process-2 is the modern lap formation process. Process-1 is also still in use in many spinning units. In the Process -1, the range of 16-32 carding sliver cans is doubling and drafted in the sliver lap former and the delivered lap sheet is wound onto the spool, which is known as “Sliver Lap.”

Fig. – Lap Preparation and Drafting Zone

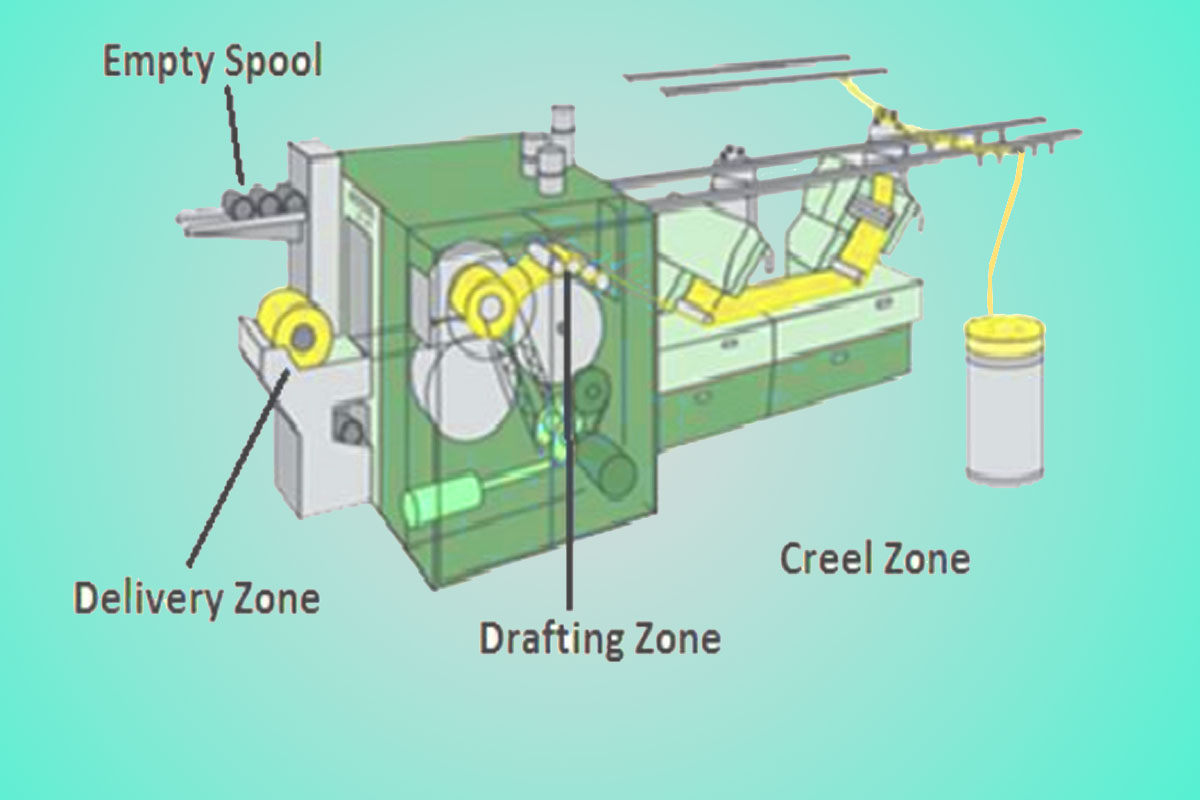

Operations of Lap former Machine (Zones):

Creel Zone:

The creel zone also known as feeding zone. 16-32 Draw Frame slivers is passes through guide roller, guide bars & fed to drafting zone.

Guide Roller:

It guides to the feeding slivers and work as a stop motion when feed sliver break.

Calendar rollers & Lap formation:

By means of rollers and stop motion, the slivers are fed side by side. Then the slivers enter in drafting zone and then calendaring zone to produce a compact lap. Then the lap is wound on to cylindrical Spool. In the lap former, the material passes through a light/slight draft.

Doffing of Lap:

The Lap former machine doffs the full lap automatically, when the desired length of lap is wound on to the spool. And during doffing the empty spools are taken from the reserve holder by the machine and the next round of winding begins.

Fig. – Different Zones of Lap Former Machine

Jljl55phlogin – time to get logged in and play! Hopefully the wins today are good ones. Keeping my fingers crossed for a good session!. jljl55phlogin

Alright, sv388tructiepph … another one I haven’t tried yet. Anyone got any experiences they’d like to share? Don’t be shy! Check it out yourself: sv388tructiepph

Heard some buzz about jili711. Gonna try it out and see if I can hit the jackpot. Let’s do this! I am pumped so see this jili711!

Yo, has anyone else tried 88winapp? Downloaded it and was surprised by how smooth everything runs. Games load fast, haven’t had any crashes. If you’re looking for a solid mobile experience, definitely check out 88winapp.

Downloaded the 15winapp app and I gotta say, it’s pretty neat. Easy to use, and I like the layout. Definitely a good option if you’re looking for a mobile experience. Give 15winapp a thumbs up from me!

Just checked out 234vipentrar. Quick loading times, decent variety of games. Nothing that blew me away, but solid, reliable, and fun. Def recommend giving 234vipentrar a try.

Casinomx77, another contender enters the ring! The game selection looks promising. Quick payouts are a must. Anyone know about their withdrawal process? Start winning at casinomx77

Yo, s92bet is pretty solid! Been playing there for a bit now and the odds are decent. Definitely worth checking out for a quick gamble. Check it out: s92bet

Just spent a little time on ur999game. The gameplay is smooth, graphics are good, and it’s easy to get the hand of it. If you want a simple game, play here ur999game

Just wanted to drop a quick note to say how helpful this post was for my research. It is refreshing to read such a well written perspective that actually addresses the questions users have. I will definitely be coming back for more updates aipilotreview

As someone who’s played many Sprunki mods, Sprunki Phase 9 Alive [GGTP] finally nails the difficulty curve. The new mechanics add strategic depth without being overwhelming. GG to the devs!

Just hopped into Sprunki Phase 9 Alive [GGTP] and the vibes are fire! No cap, the soundtrack is one of the best I’ve heard in a mod. GG to everyone involved!

88iwin huh? The name sounds promising. Gonna dip my toes in and see what’s up. Maybe it’ll become my new go-to. Have a look: 88iwin!

AF88game anyone? Checking this out tonight, hopefully it lives up to the hype. Wish me luck! and good luck to you too: af88game

Mcgame, mcgame, i am loving it! A classic I must check out. See if it lives up to all the talk, give it a go at mcgame!

Yo! If you’re looking for some solid game downloads, x7777gamedownload is your spot. Easy to find what you need and get gaming quick. Download ’em all: x7777gamedownload

Pokebet88casino is where it’s at tonight. Trying my luck hope I win big. Maybe i’ll see you there pokebet88casino!

Just signed up with canohuwin. New platform, looking forward to trying it out this weekend. Why not give it a look too canohuwin.

Yo, downloaded the 718spgameapk. Installation was quick and the gameplay’s smooth as butter. Give it a try, you might like it! Grab it here: 718spgameapk

Been playing 291bet games for a while now, definitely my go-to for some fun and excitement. Good variety and always something new to try 291bet game

Gameph login was smooth, no hiccups. That’s always a plus. Now to see if the gameplay lives up to it. Fingers crossed. gameph login