Auto Coner

The auto coner machine is a fully automatic yarn winding machine used in the spinning process in the textile industry. This machine is widely used in yarn preparation, it plays a major role for converting ring yarn cops or bobbins or packages into good quality yarn with reducing yarn faults like nep’s, hairiness, thick and thick places, which are ready for weaving or knitting. It operates automatically, reducing labor requirements.

Objectives Of Auto Coner Machine

- To remove yarn faults.

- To improve the quality of yarn.

- To wax the yarn during winding process.

- To convert small ring cops to cones or cheese, to get continuous length of yarn and produce suitable packages for Weaving or Knitting processes.

Cone Winding Process

After manufacturing the ring yarn, including different departments like preparatory process and ring department, in auto coner get final cone or cheese form so that it can be shipped to the customer for use. During the auto coner process, following functions are met.

Scanning And Faults Removing

Splicing Of Broken Or Cut Yarn

Bigger Package

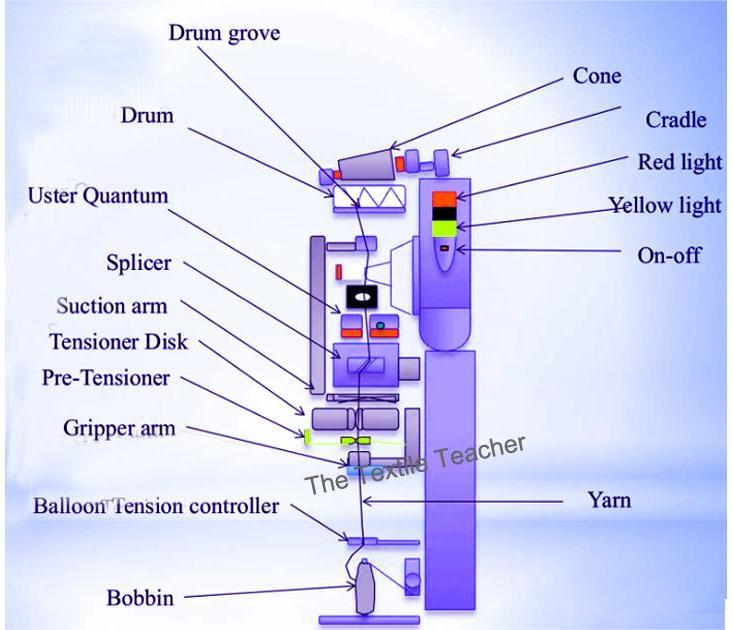

Parts Of Auto Coner & Its Function

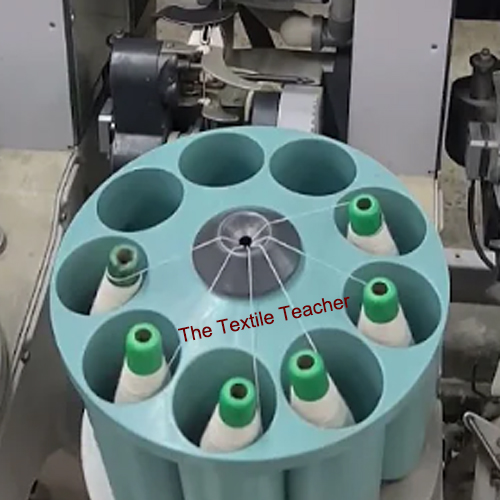

Bobbin Magazine:

The Bobbin Magazine is a storage and feeding unit that holds and transfer bobbins. When a empty bobbin is removed, an full one is automatically fed into the machine, for a continuous operation.

Bobbin Holder:

The bobbin holder is the part that holds the ring bobbin properly in place for unwinding process.

Bobbin plate:

Bobbin plate is helped as a base or support for the bobbins which replaces the empty bobbins with the filled bobbins one by one.

Yarn Tensioner & Waxing Unit:

Yarn tensioner impart required tension to the yarn during unwinding from ring bobbin to winding. Wax motor runs wax roll continuously. The function of wax is to makes smooth yarn surface by lay down the hairy fibres. For knitting mostly waxed yarns are used.

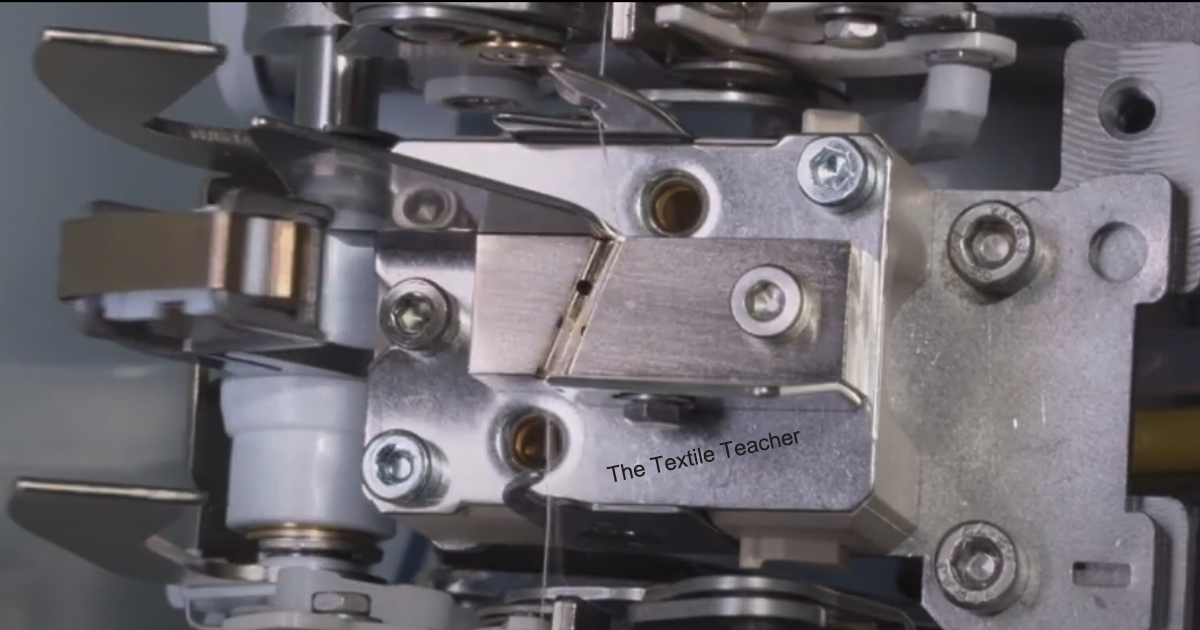

Yarn Splicer:

The splicer is mounted on the auto coner machine. The function of splicer is to joint two ends of yarn without any knots means, the splicer is automatically untwist and twist the yarn with air splicer unit.

Suction Pipe:

The suction pipe sucks the yarn end from the ring bobbin and takes it to the splicing unit.

Waste Suction Pipe:

The waste yarn is cut off during splicing and sucked by the waste suction pipe.

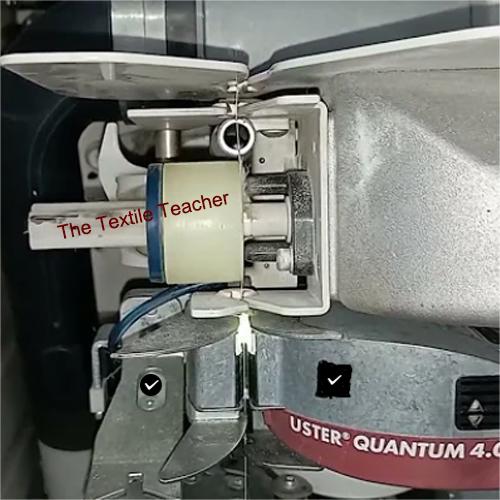

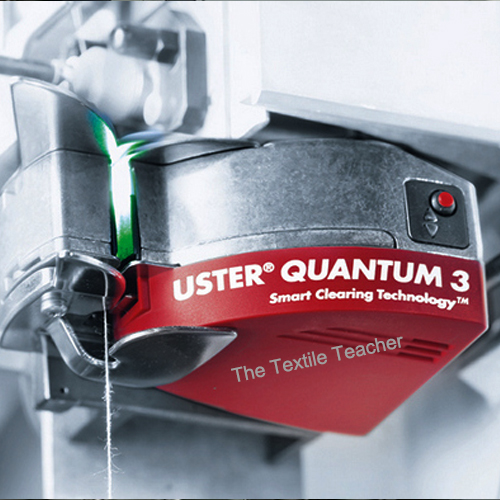

Yarn Cleaner:

A yarn clearer is a electronic yarn clearer device, which use for to remove faults from yarn like neps, thick place, hairiness, thin place etc. according to the set value. Yarn clearer increase the spun yarn quality. and Therefore, the fabric made from it has a clear, uniform yarn mainly important for excellent operation of high-speed weaving machinery.

Cradle:

The cradle is used as a package holder, mounted on top of a groove drum.

Winding Drum:

It is a metal grooved drum and has a coated or polished surface. It helps for cross winding of yarn packages.

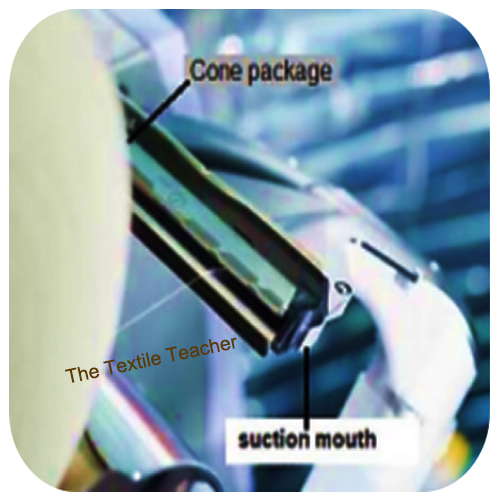

Suction Mouth:

When the yarn breaks during the winding process the cone or cheese moves slowly in the opposite direction, during that period the suction mouth sucks the broken yarn end from the cone or cheese package and moves it to the splicing unit.

Winding:

The Auto Coner machine wound yarn from a ring cops to a new package (Cone or Cheese), maintaining uniform tension and ensuring stable, compact yarn packages.

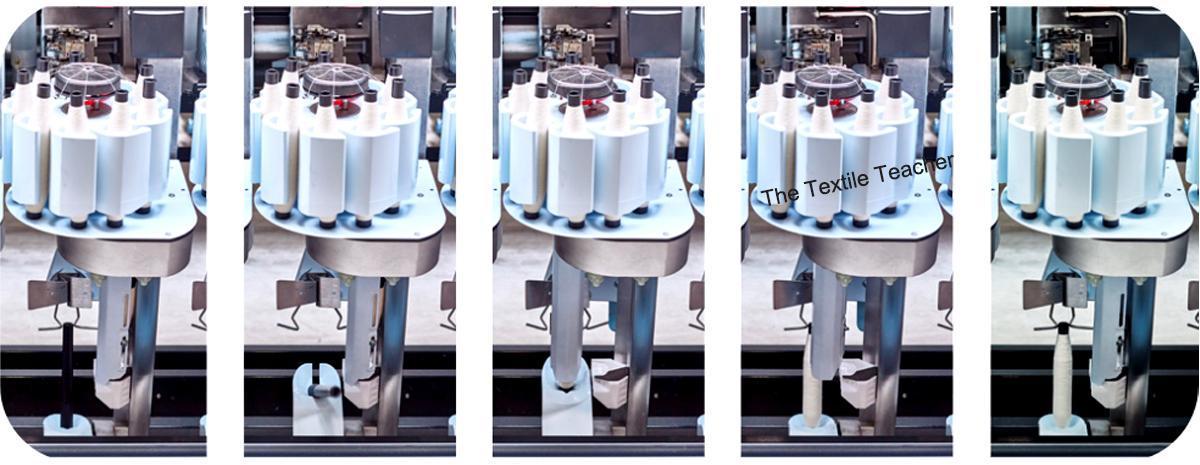

Doffing:

The machine automatic doffing fully wound package and replace with empty one

Defects In Cones

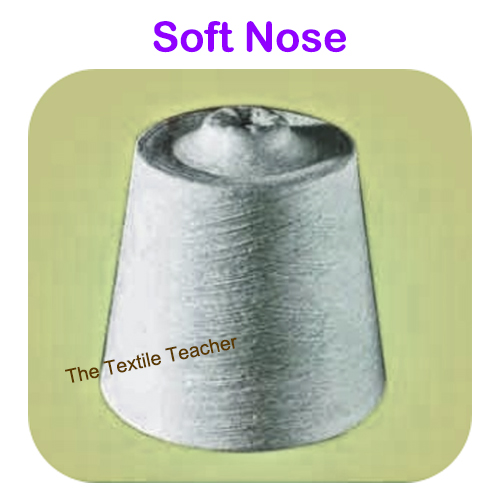

Soft Nose

Stitches On Cone

Ribboning Or Patterning

Soft Package

Bell Shape Cone

Collapsed Cone

真免费!价值万元资源,不要一分钱,网址:https://www.53278.xyz/

Hey all, has anyone ever used 555wincom? I’m curious! Looks like a nice platform for gaming. You can check it out here 555wincom.

Just trying to 8857login to my account… hope I remember my password! Anyone else having trouble? lol. 8857login

Yo, need a quick agbong88login. I heard this gives direct access. Is it reliable? Tired of the endless redirects. Feedback, anyone? Have a glance: agbong88login

Jilislotwin is all about the slots, man. If you’re a fan, this is your spot! Lots of different games and some seriously fun features. Hit up jilislotwin and spin to win!

Been keeping an eye on kqxsag for lottery results, and it’s been pretty spot on. Quick and reliable. Good resource to have! Check out kqxsag!

Downloaded the Lotus 365 apk and it’s way smoother than using the website on my phone. Betting on the go is now a breeze! Get that lotus 365 apk!

A really good blog and me back again.

Alright, so I checked out mxwinner. Seems pretty solid, easy to navigate, and I didn’t run into any weird glitches. Definitely worth a look if you’re searching for something new. Check it out here: mxwinner

Just signed up for 580betlogin, and the process was super quick. No annoying hoops to jump through, which is a major plus. Solid first impression. Find it here: 580betlogin

Okay, 55qqbet gets the thumbs up from me. It’s easy on the eyes and seems to be well put together. If you’re considering it, give it a try. Visit their site: 55qqbet

每天都在战争,希望2026和平.