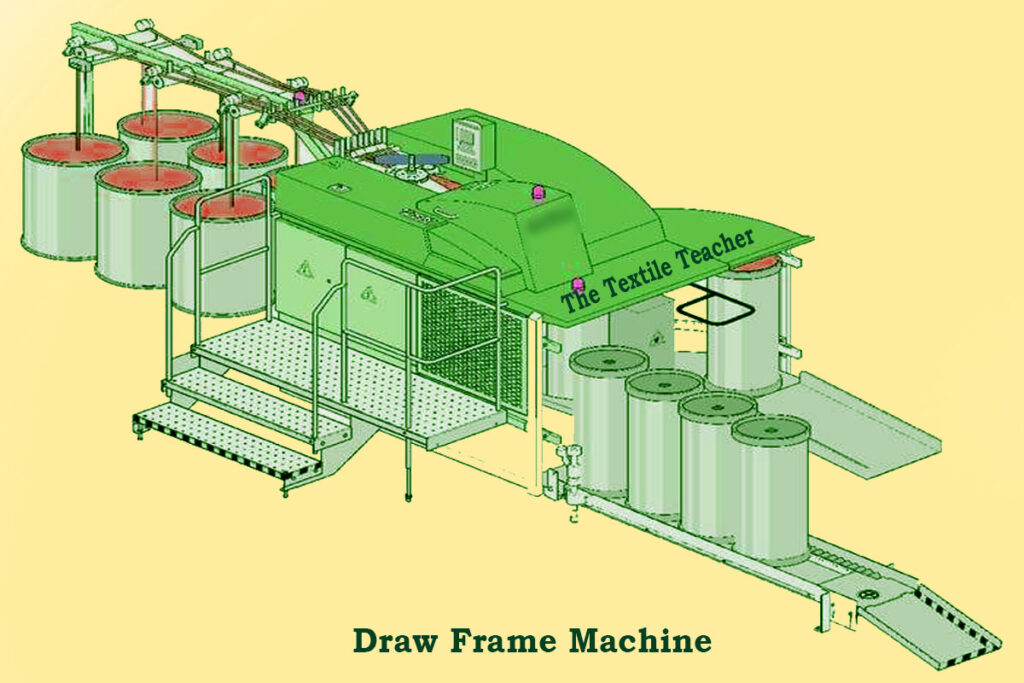

Purpose of Drawing:

The purposes of drawing (Draw Frame) are to improve the uniformity of the slivers and to straighten the fibres in the slivers. The improvement in uniformity is due to the doubling and drafting of eight to ten slivers can into one. The straightening of the fibres is accomplished by drawing fibres by each other. The straightening is important because it arranges the fibres more parallel to each other and to the direction of the fibre strand. When the fibres are well straightened, the arrangement helps in producing uniform, strong and smooth yarn.

Objectives of Draw Frame Machine:

- To straighten the curled and hooked fibres.

- To make the fibres parallel to their neighboring fibres.

- To improve uniformity of fibres by drafting and doubling.

- To reduce mass per unit length of sliver.

- To remove micro dust from slivers by air suction pipe.

- To blend raw material perfectly.

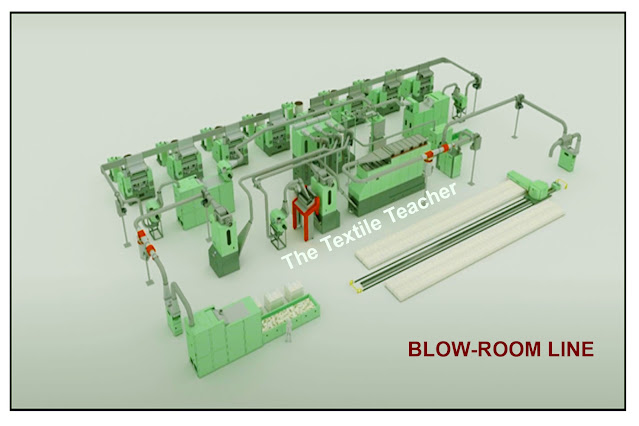

TYPE OF DRAW FRAME:

- Breaker Draw frame: Feed material is carded sliver. During this process 8-10 carded slivers are fed to this machine to produce more parallelized breaker sliver.

- Finisher Draw frame: Feed material is breaker draw frame drawn sliver. During this process 8-10 breaker slivers are fed to this machine to produce more parallelized & uniformed finisher sliver.

Operating Principle

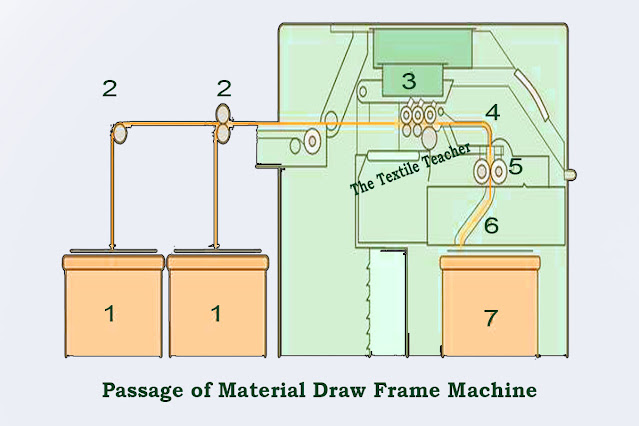

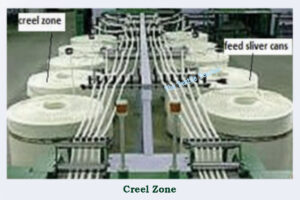

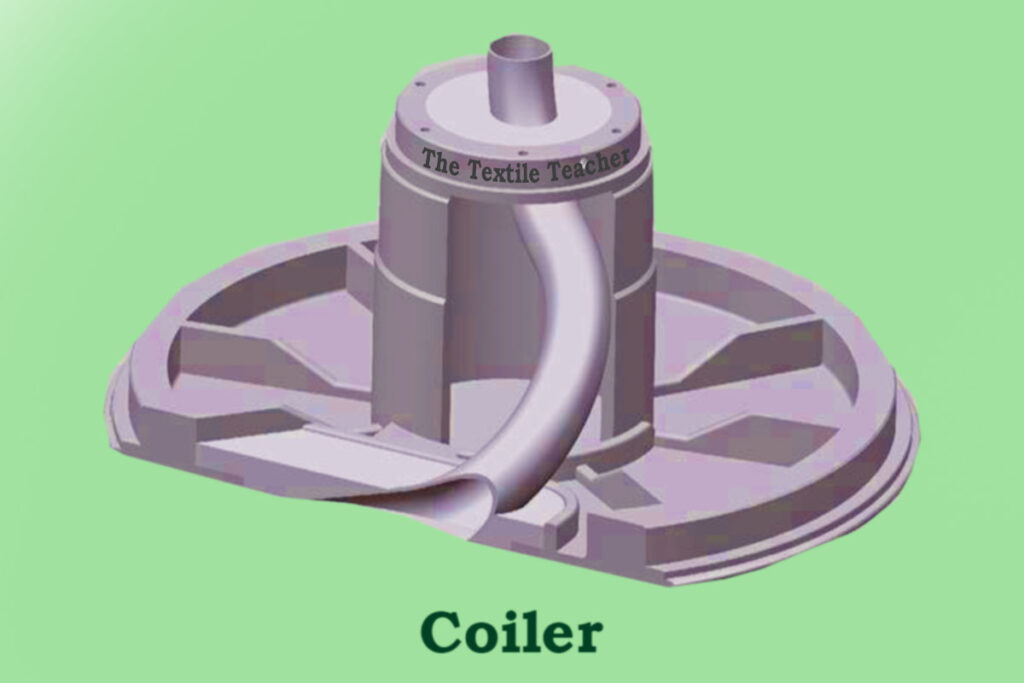

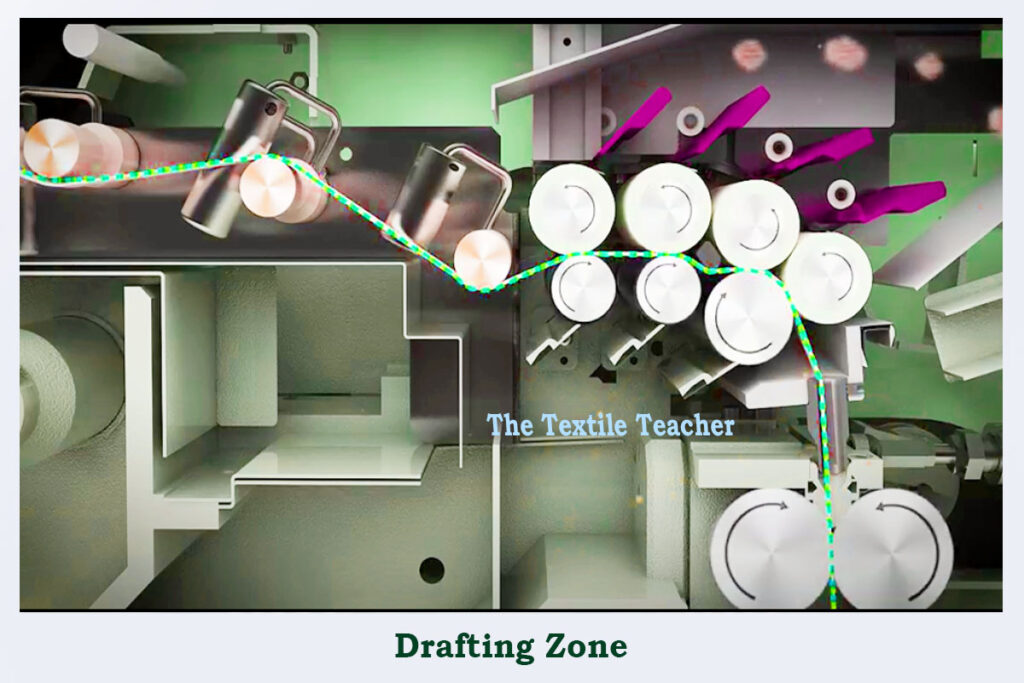

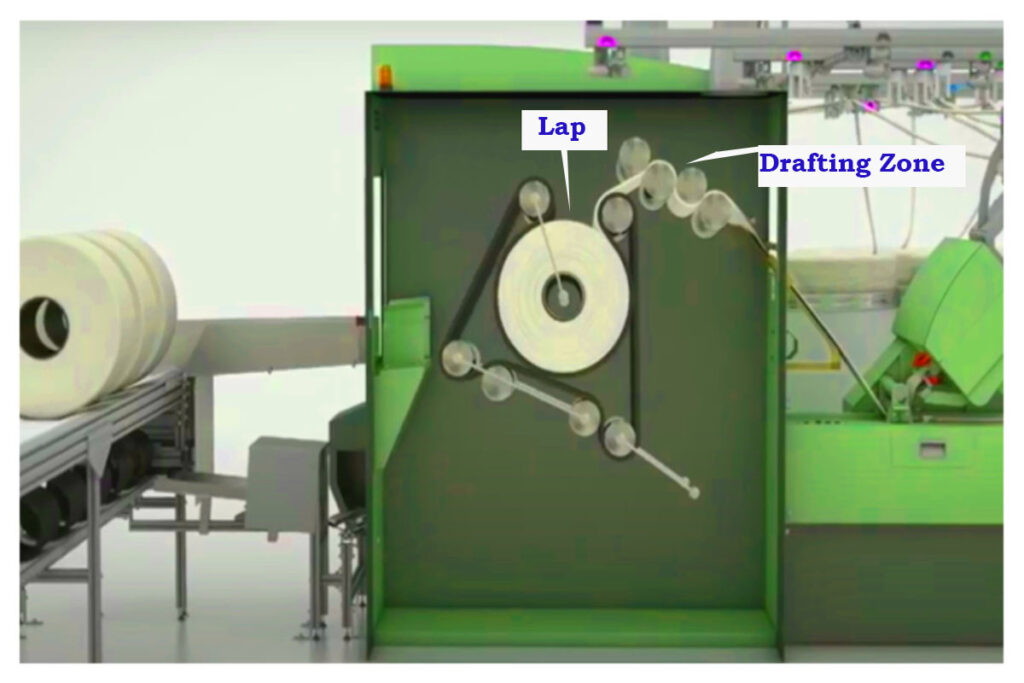

The passage of material of Draw Frame machine is Eight to ten card or draw frame slivers (see Fig. Passage of Material Draw Frame Machine) are fed to the drafting zone (3). A feed roller pair (2) is located above each can (1) to enable the feeding step to be performed in a controlled manner without false drafts. The feed roller pairs are mounted in a creel zone and each is positively driven. The slivers running into the drafting zone leave it, after a draft of 8 to 10, as a web lacking significant cohesion. In order to avoid disintegration of the web, which would otherwise be unavoidable at the high operating speeds currently in use, it is condensed into a sliver immediately after the drafting arrangement. This sliver is then (for example in some makes) guided through a tube (4) via a passage (6) of the sliver tube into a can (7), in which it must be laid in clean coils with optimal utilization of the space in the can. To enable the can to take up as much material as possible, the sliver is compressed by passing it through calendaring rollers (5).

DIFFERENT ZONES OF DRAW FRAME MACHINE

CREEL ZONE:

GUIDE ROLLER:

AUTO LEVELER:

DRAFTING ZONE

SLIVER COILING:

DOFFING OF CANS:

THE TASK OF THE DRAW FRAME

EQUALIZING

One of the main tasks of the draw frame is improving evenness over the short, medium and long term. Card slivers fed to the draw frame have a degree of unevenness that cannot be tolerated in practice, and slivers from the comber contain the infamous piecing’s; these must be obscured. It should be noted, however, that short-wave sliver evenness is not as sometimes assumed the sole criterion for evaluating the performance of the draw frame. Equalizing is always and in any case performed by doubling, and can optionally also be performed by additional auto leveling.

PARALLELIZING

To obtain an optimal value for strength in the yarn characteristics, the fibres must be arranged parallel in the fibre strand. It is mainly the draw frames task to create this parallel arrangement. It fulfills this task by means of the draft, since every drafting step leads to straightening of the fibres. The value of the draft must be adapted to the material, i.e. to several fibre parameters, mainly:

- The staple length;

- The mass of the fibres;

- The volume of the strand;

- The degree of order (parallel disposition).

BLENDING

In the spinning process every doubling produces simultaneous blending especially the 8-10 doublings on the draw frame. The doubling also provides a degree of compensation of raw material variations by blending, which occurs simultaneously. This result is exploited in particular in the production of blended yarns comprising cotton/synthetic or synthetic/synthetic blends. At the draw frame, metering of the individual components can be carried out very simply by selection of the number of slivers entering the machine. Eg.- 70:30 blend (P:C).

DUST REMOVAL

To remove dust to the greatest practical extent at every possible point within the overall process. Unfortunately, dust removal can only be carried out to a significant degree. Since a large proportion of these very small particles (dust) adhere relatively strongly to the fibres. The draw frame is therefore a good dust-removing machine. On high-performance draw frames equipped with appropriate suction systems.

Pingback: #What is Speed Frame Machine? Objectives of Speed Frame Machine Parts or Zones of Roving Frame Machine -

E aí, turma da aposta! A betnacional4 parece ser uma boa opção para quem gosta de apostas esportivas. Tem uma boa variedade de esportes e mercados. Vale a pena dar uma olhada! Clica aqui: betnacional4

Been using 5588Bet for a bit now, and I’m liking the interface a lot. Easy to navigate, good odds, good selection. If you haven’t checked it out, take a look: 5588bet. Don’t bet more than you can afford to lose!

Need to get in touch with Betmaster? Contactobetmaster seems like the place to go. Hope their support is quick! Find what you need at: contactobetmaster

Alright, qh88bets is where it’s at if you want options. They got so many different ways to bet. I was on there for hours. Check out qh88bets!

Heard some buzz about 888jiliactivity, and gotta say, it lives up to the hype! Really enjoyed the overall experience they offered. Explore the 888jiliactivity if you fancy!

Bet117bet has a good selection of games and the site is easy to navigate. It’s a solid choice if you’re looking for a reliable place to bet. Give bet117bet a try!

Just logged in to PH22VIPLogin again! Smooth experience as always. No lag, and withdrawals are processed quickly. Highly recommend giving ph22viplogin a look!

Trying my luck at Banca30T88! Decent interface and easy to navigate. Fingers crossed for a big win! Check it out: banca30t88

01Win55 is alright. Not the flashiest site, but it gets the job done. They’ve got a decent selection of games. Take a look at 01win55 and see if it’s for you!